Embracing Advanced Timber Scanning Technology at Programmed Timber Supplies

We’re thrilled to announce the successful installation of some of the world’s most advanced timber scanning technology at Programmed Timber Supplies. This cutting-edge technology, used in the production of components, ensures our customers benefit from enhanced quality control and a more tailored product offering.

This technology allows us to meet far more precise specifications consistently, outperforming traditional visual grading methods in terms of accuracy and efficiency.

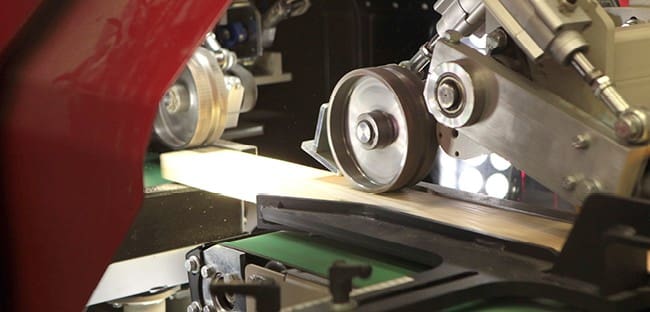

Operating at high speed, the technology employs continuous X-ray scanning, laser detection of shape, form, and grain, and utilises both black & white and colour imaging of each board. Every characteristic of every board is meticulously analysed and processed to maximise recovery and ensure the production of fit-for-purpose components every time.

Our furniture component customers can now have their specific requirements met with even greater precision. Additionally, we can supply lower-value components with specific characteristics to enhance their usability.

Such outcomes were previously unattainable on a full manufacturing scale. The application of this new technology elevates the standard of component supply, optimises resource utilisation, and delivers superior products for the user. We’re excited about the future of timber scanning at Programmed Timber Supplies!