Introducing Clear End Zone Components at Programmed Timber Supplies

Harnessing New Technology

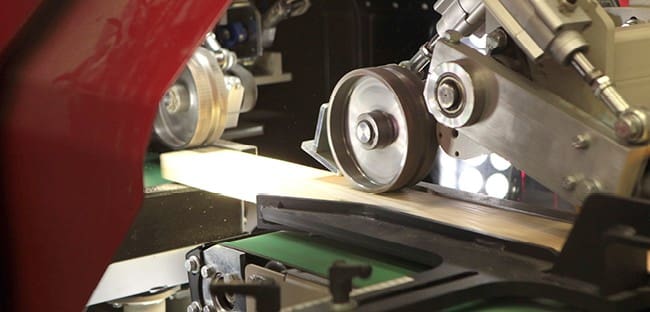

We’re excited to announce a new offering at Programmed Timber Supplies – the production of clear end zone components for frame and truss manufacturers. Thanks to the installation of our state-of-the-art Golden Eye scanner, we’re now able to produce components with a CLEAR END ZONE.

What is a Clear End Zone?

This feature ensures a defect-free zone at the end of each component, where fixings such as plating or nailing typically occur. In addition to being defect-free, the clear end zone allows only minimal wane, which is significantly less than the allowance under structural grading rules. This aligns more closely with the requirements of plate manufacturers.

Product Range and Benefits

Our clear end zone components are available across our entire product range, including studs, webs, nogs, and truss trimmers. The key benefit of these components is the reduction of waste. A defect occurring at the end of a standard component can render it unsuitable for fixing, necessitating replacement. This not only creates waste but also adds the cost of reprocessing the rejected component.

Safety First

From a Work Health and Safety (WHS) perspective, clear end zone components also help to mitigate the risk of accidents during nailing. By eliminating defects that could cause a nail to skew, we reduce the chance of operators injuring themselves – an all too common occurrence in the industry.

A Smart Choice

Whether you’re purchasing components or cutting your own, opting for clear end zone components is a smart choice for enhancing efficiency and achieving significant savings in your manufacturing costs.

Contact Us

For more details on our supply of clear end zone components, please don’t hesitate to contact us.